Assessing welded joint after examination

Assessing welded joints is an important connection between realizing and approving welded work. A visual welding inspector must have knowledge of the possible imperfections that may occur in addition to good eyes. An understanding of quality requirements for welding and an understanding of the welding process-material combination used is also very important. Do you want to learn how to visually assess welded joints? Do you want to gain insight into visually examining fusion welds, quality levels, and applicable standards at the imperfections? Destructive Testing Lab Element Materials Technology will take you into this world.

Intended for

Welding inspectors, welding coordinators, welding technicians, quality assurance personnel and anyone else who has to deal with the visual inspection of welds.

Topics

- Assessing macros

- Assessing Shear Samples

- Assessing Hardness

- Visual welding examination principles according to NEN-EN-ISO 17637

- Quality levels for imperfections according to:

- NEN-EN-ISO 6520

- NEN-EN-ISO 5817 for steel applications

- NEN-EN-ISO 10042 for aluminum applications

You will learn to apply suitable measuring tools. After this workshop you will be able to make an objective judgment of both butt and fillet welds based on the quality level applied. You will also be able to report on visual weld assessment.

General information

| Location: | Elektrolas, Waalwijk |

| Costs: | 175 euros (excluding taxes) |

Upon completion, you can receive a certificate of participation that will help you demonstrably keep your knowledge up to date. Participation will earn you points towards the framework certificate.

This workshop at your location

Do you have a larger group of employees for whom this workshop would be interesting? Elektrolas can also provide workshops at your location. Please contact us at 0416-235036. Or let us contact you.

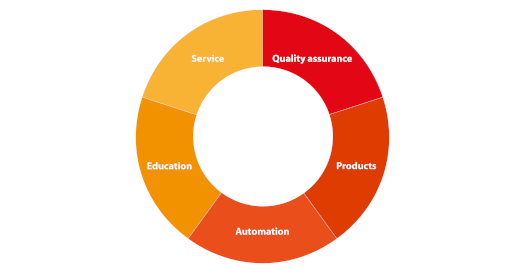

Our overall approach

When it comes to welding, elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.