Basic welder: a real craftsman or woman

The basic welder is a welder who performs various production and construction welding work. He joins parts, usually sheet metal and angle profiles (sometimes pipe), using various welding processes. This often involves simple, non-certified welding. The basic welder can be found in the workshop of almost all types of companies in the metal industry where welding is part of the production process. Think of construction companies, companies for machine and equipment construction, electrical engineering transport and shipbuilding.

What does a basic welder do?

The basic welder often works in a combination job as a welder/composer, welder/construction fitter, or welder/pipe fitter. Assignments are carried out independently. He often makes series of the same product. From a drawing, the basic welder reads which weld he should make. He pays attention to quality, safety and the environment.

The basic welder makes, repairs and adjusts construction parts by applying various techniques. The main activities are:

- Grinding (preparation)

- Welding (joining)

- Screwing (joining)

- Drilling, milling, sawing (machining)

- Edging and bending (forming)

The basic welder receives orders from the cooperating welding foreman and/or workshop manager, to whom he also reports.

The competences of a basic welder

Good workmanship requires that the person possess competencies that are decisive for the job, the profession. A basic welder should have:

Independence

A base welder is supervised by his direct supervisor and independently performs various production and construction welding.

Complexity

The basic welder is physically strong and can work in hard-to-reach places both alone and in a team.

What is part of the basic welder training?

In order to grow in the profession and have the right competencies, a learning path has been set out for the basic welder. This consists of welding training, welding courses and workshops.

- MAG skill training level 2

- Workshop making WPS

- Workshop Drawing

By growing in the work, the talent is developed, the craftsmanship increases, the appreciation grows, other connections are made, and solutions are found more quickly.

Career opportunities for a basic welder

Are you ambitious and do you want to grow within welding technology. Then there are various positions / professions for which you can learn more:

- All-round welder

- Pipe welder

- Hygienic welder

- Cobot welder

- Welding foreman

- Welding coordinator

- Welding inspector

- Welding engineer

Elektrolas supports operational and managerial staff to take the right steps by providing them with professional training.

Elektrolas advises the right route

By taking a project-based approach to employee training, you can make strategic decisions. We advise you on the long-term direction you can take with your employees and the training you need to achieve that. We have our own welding school in Waalwijk, where we offer all training courses and workshops. This makes the flow of the learning process very smooth. Would you like to talk to us about a training program for cobot welders or do you want to look at your entire workforce together? Contact our Training Department at 0416-235036 or lasschool@elektrolas.com. You can also leave your details and we will contact you.

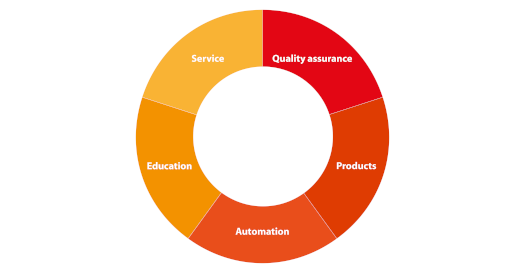

Our Overall Approach

When it comes to welding, elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.