Cobot applications - What can a cobot offer?

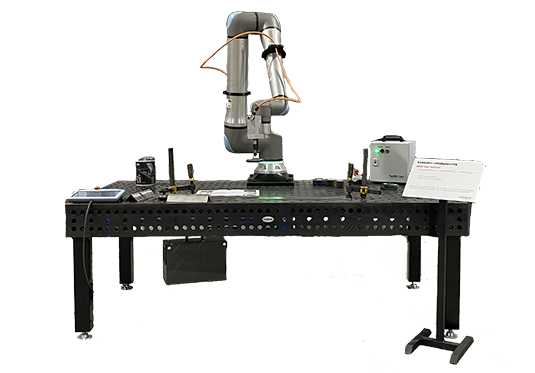

Welding with a cobot

Welding with the cobot can be done either for TIG or for MIG/MAG processes. It is also possible to hang the cobot upside down. This gives more space on the welding table. Besides welding with the cobot, it is also possible to grind, sand or polish. Did you also know that it is possible to combine one cobot arm with different processes, such as welding and sanding?

Grinding, sanding and polishing

Grinding, sanding and polishing with the cobot are becoming more common in welding shops. Previously, only welding was done with the cobot. Since the demand for multiple applications with the cobot. Is now possible to use it on multiple processes. The quick change system makes it possible to integrate this on one cobot arm.

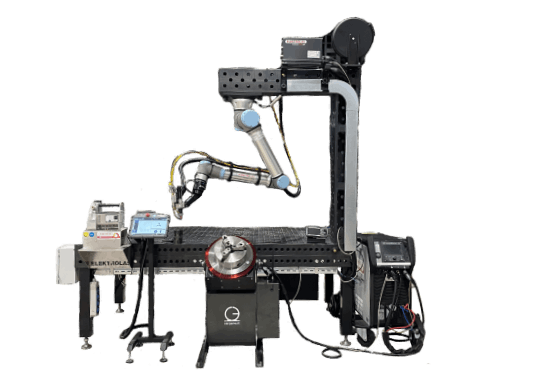

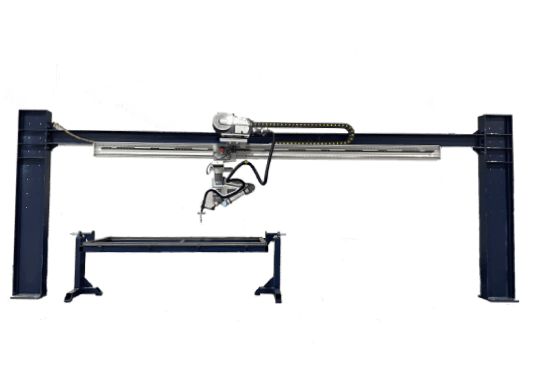

Cobot on a track

Cobot on a track increases the range of the welding operations. This solution is often found where tasks are performed over a greater distance. Here, the cobot is mounted upside down. Allowing it to move smoothly back and forth. This allows also the welding work to be completed without additional tension forces.

Watch the cobot in action

Wondering how the cobot is used at different welding shops? Then watch one of the videos below:

Unique cobot parts

In addition to preparing cobot projects at the COBOT center, parts are also produced. These parts serve to strengthen the cobot solutions or are added as supplements. In this way, we not only ensure the quality of our cobot projects, but we can also respond flexibly to specific needs and offer innovative solutions to our customers.

Ellas cap

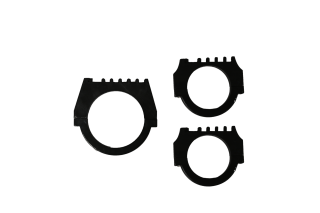

torch clamps

Remote control

Transport pallet

Extra control

Touch standard

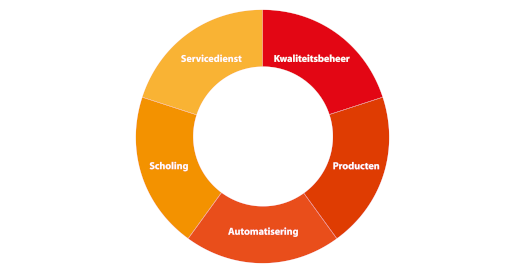

Onze totaalaanpak - De Schijf van Vijf

Alle kennis en middelen rond lasvragen hebben wij in eigen huis. Wij zijn één aanspreekpunt voor alle betrokkenen in het lasproces, van aanbesteding tot kwaliteitscontrole. Elektrolas is een totaalaanbieder op lasgebied. We borgen kwaliteit, geven scholing, innoveren processen, verkopen en verhuren producten en bieden service op lasbenodigdheden.. Dat is onze Schijf van Vijf. Vijf diensten die elkaar versterken. Zo zorgen wij dat onze klanten klaar zijn voor de toekomst.