Cobot programming training

In our training we have taken the elements from the core training that are relevant in welding and added our welding experience and expertise. Read more about the basic and advanced training below.

Base Training

It is the first time for the participants to work with a cobot. Therefore, during the basic training, the focus is on general knowledge about the cobot. At the end of the day, the participants understand the entire layout of the program and can make a weld with the cobot.

Topics

- Working with the cobot software

- Programming with the cobot

- Creating structure in programs

- Welding with the cobot

- Changing welding programs

Intended for welders and workshop supervisors who have no experience in working with a cobot.

Advanced Training

Besides the basic training there is also a training for more in-depth programming. There are so many possibilities with the cobot. Think of multilayer welding, circular welding and copying programs. There are also pitfalls in programming that the participants will experience during the training. They will work with real programming rules instead of the simpler pre-programmed commands.

Topics

- Working with external equipment such as welding machine, manipulator, cold wire (connections)

- Creating programs in the right way (structure)

- Working with several welding sections (copying)

- Working with various tools (torch, control point)

- Calling up jobs

- Inner corner welding / outer corner welding

- Multilayer welding and Weaving

Intended for welders and workshop supervisors who already have some experience working with the cobot.

General information

| Location: | Elektrolas Waalwijk |

| Costs: | 725 euros (excluding taxes) |

Upon completion, you can receive a certificate of participation that will help you demonstrably keep your knowledge up to date. Participation earns you points for obtaining the framework certificate.

For more information contact us on +31 (0)416 235036.

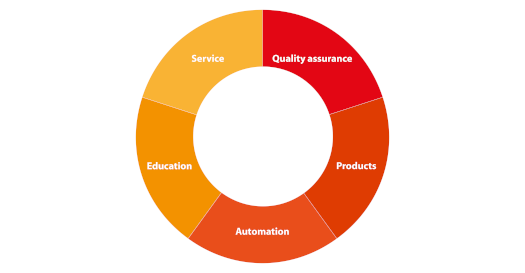

Our overall approach

When it comes to welding, elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.