Davy

‘I want every solution to contribute

to simplicity and clarity.’

Davy van der Steijn

IT Process Manager

T: +31 (0)416-336777

E: davy.vandersteijn@elektrolas.com

to simplicity and clarity.’

Davy van der Steijn

IT Process Manager

T: +31 (0)416-336777

E: davy.vandersteijn@elektrolas.com

"Elektrolas takes the welding world into the future"

‘Data is also becoming increasingly important in the welding world, although not everyone in our industry seems to realise this yet.’ Speaking is Davy van der Steijn, Product Data Specialist at Elektrolas. His daily task is the input, processing and management of product data. This digital information is continuously consulted by internal and external systems. Hence the databases, which he sets up in a consistent and structured manner, support all Elektrolas divisions. To the entire Disk of Five, in other words.

Research and good analysis

‘I have been working at Elektrolas since January 2021, having gained work experience in online marketing, among other things. I took various courses, including MBO application development and HBO Business Innovation. There I experienced that problem solving starts with research and good analysis. Moreover, in project groups I learned to work together with people who were all specialists in their own field. Maybe that's why it clicks so well with my colleagues. Which is nice, because the nature of my job makes internal coordination with all other departments necessary, after all. Because we can be straightforward with each other, we arrive at the best solutions faster. Not everything can happen in one day, of course. When visiting the website and Our Welding Portal, customers may already have noticed that changes have taken place in the classification of the categories and that product data are constantly being added. But towards the future, there is much more to come.’

Product data

‘The welding industry still pays comparatively little attention to product data. In this respect, Elektrolas has a head start. We use our product information system (PIM) for our own ERP system, as a knowledge base for our product specialists, for the product displays on the website, for our Google findability and of course for Our Welding Portal. Our customers also reap the benefits of our digital information. For example, when ordering equipment and consumables online and when they receive an automatic notification from us that new machine certificates or welder certificates have been uploaded. Much of this data we link directly to the computer systems of customers who want live access to information they need for the continuity of their production department. The reverse also happens; we can import the data of more and more of suppliers directly. Ultimately, this benefits all our customers. After all, they need to be able to rely on correct product data.’

Fixed structure

‘You can imagine how important it is to store data in a usable and reliable way. The files must follow a fixed structure. We decided to invest extra in the process of processing and management. This starts as early as the entry of a new item, such as a new product in our range. We could have chosen the former, fairly complicated way. Then we would have lost a lot of time each time, while errors and inconsistency lurked. Instead, we streamlined our systems so that everything can be entered according to the same protocols. I want any solution to contribute to simplicity and clarity. Rather think carefully beforehand, so that you can develop something that works at the push of a button. So typical of Elektrolas: we have prioritised a long-term vision when it comes to automation, knowing that this will pay off over the years.’

Welding Workshop of the Future

‘Elektrolas has a vision of the Welding Workshop of the Future. There is an industrial revolution going on. In my experience, the metal industry is not yet at the forefront of this. The cobot is one such innovation that Elektrolas is already fully committed to. But it is actually only a relatively small part of the transition towards robotisation, among other things. Data and automation obviously play a huge role in this. Companies that make that leap now will benefit in the long run. Elektrolas is therefore already taking the welding world into the future.’

More info on Products

More info on Our Welding Portal

More info on Welding Workshop of the Future

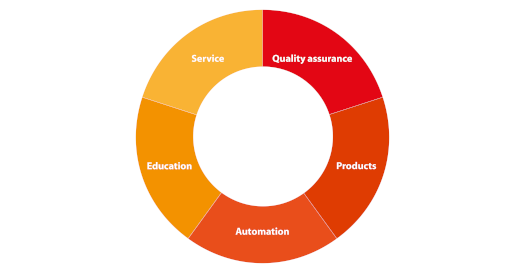

Our Overall Approach

When it comes to welding, elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.