Joost

‘I don't believe in sales. I do believe

in filling a need.’

Joost van den Hooven

CEO

T: +31 (0)6 25108991

E: joost@elektrolas.com

in filling a need.’

Joost van den Hooven

CEO

T: +31 (0)6 25108991

E: joost@elektrolas.com

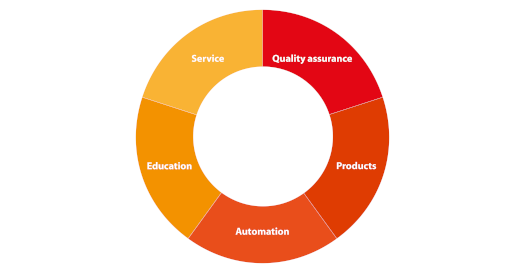

We challenge our relationships to keep developing

Joost van den Hooven is the owner of Elektrolas. But other titles suit him too. Innovator. Entrepreneur. Welding transition coach. Concept creator. ‘Our work is not about ón us. All Elektrolas products, knowledge and processes must benefit our relations. These are companies where welding is part of the production process. Although the welding world is basically traditional, the sales market is evolving. Production companies increasingly need traceability and quality assurance, also because their customers demand it. Elektrolas' Disc of Five offers an integral approach for this: sales, rental, service, training and quality management. All certainty under one roof, in other words.’

Waalwijk

Joost's entrepreneurship began in 2000 when he and partner Joris van Balkom took over a welding supplies company and put his own spin on it. That was after studying HTS Business Management. The adventure with Joris lasted 10 years, until he found love and emigrated to Mexico. ‘In 2009, we built our premises at Haven Zeven in Waalwijk. Elektrolas continued to grow. In 2016, we built an extension to give us more space for the Elektrolas Welding School, offices and warehouses. We now work here with 22 colleagues. The team includes customer advisers, welding technicians (IWTs), teachers, logistics staff, customer support and back office staff.’

Predictable quality

‘I don't believe in selling. I do believe in filling a need. Welding is a beautiful process. Although no-nonsense, we still see enough practical and theoretical challenges to make the profession better. From the very beginning, we have studied not only equipment and the weld itself, but also material compositions and construction methods. It is important for a manufacturing company to deliver predictable quality that meets all requirements. You can tighten a bolt if you need to, but how can you be sure that a weld is satisfactory? While you can run a destructive test on it, you have to be confident that the next one will meet exactly the same requirements.’

Between design and implementation

‘There is often a gap between what the end customer demands and what the welding shop performs according to its own judgement based on experience. Engineers, engineers, designers and product managers want not only an optically beautiful weld, but above all a guarantee that every weld meets specifications. Elektrolas has jumped into that gap. We are the bridge between design and implementation. Our role - for us, of course - therefore goes far beyond simply selling equipment and consumables. Our consultants look at what is going well and what process improvements are necessary. We train welders in the Elektrolas Welding School, provide the right equipment from our sales or rental department, guarantee the quality of the end product and offer 24/7 technical service. I am proud that we have shaped Elektrolas into a complete partner for the manufacturing industry.’

Own responsibility

Ask the Elektrolas team to describe Joost and there is soon admiration for his gut feeling and unlimited ideas. And for his perseverance and the boundless energy with which he runs half marathons. ‘At school, I could never sit still. I always want to be busy. The fact that I see and remember everything is fortunately my strength. I don't believe in hierarchy. I do believe in the personal responsibility of our people. That is why we share plans internally and I like to step back when I see that things are going well. The atmosphere within Elektrolas is very important to me. I believe in warmth and security. People should be able to do their work in a place where they feel comfortable. Hence the cosy office interior, the bar area where we can confer and a catered lunch every day.’

The welding workshop of the future

‘We challenge our relations to keep developing. With them, we share our vision of the welding workshop of the future. If we want to retain the manufacturing industry for the Netherlands, they will have to focus on smarter working, flexible working and digitalisation. Meanwhile, we also expect the demands on the end product to become increasingly stringent. Less weight, fewer transport movements and a reduction in cost price. Elektrolas' services are constantly adapting. We are ready for the future!’

Read more about Elektrolas

Read more about the Welding Workshop of the Future

Waalwijk

Joost's entrepreneurship began in 2000 when he and partner Joris van Balkom took over a welding supplies company and put his own spin on it. That was after studying HTS Business Management. The adventure with Joris lasted 10 years, until he found love and emigrated to Mexico. ‘In 2009, we built our premises at Haven Zeven in Waalwijk. Elektrolas continued to grow. In 2016, we built an extension to give us more space for the Elektrolas Welding School, offices and warehouses. We now work here with 22 colleagues. The team includes customer advisers, welding technicians (IWTs), teachers, logistics staff, customer support and back office staff.’

Predictable quality

‘I don't believe in selling. I do believe in filling a need. Welding is a beautiful process. Although no-nonsense, we still see enough practical and theoretical challenges to make the profession better. From the very beginning, we have studied not only equipment and the weld itself, but also material compositions and construction methods. It is important for a manufacturing company to deliver predictable quality that meets all requirements. You can tighten a bolt if you need to, but how can you be sure that a weld is satisfactory? While you can run a destructive test on it, you have to be confident that the next one will meet exactly the same requirements.’

Between design and implementation

‘There is often a gap between what the end customer demands and what the welding shop performs according to its own judgement based on experience. Engineers, engineers, designers and product managers want not only an optically beautiful weld, but above all a guarantee that every weld meets specifications. Elektrolas has jumped into that gap. We are the bridge between design and implementation. Our role - for us, of course - therefore goes far beyond simply selling equipment and consumables. Our consultants look at what is going well and what process improvements are necessary. We train welders in the Elektrolas Welding School, provide the right equipment from our sales or rental department, guarantee the quality of the end product and offer 24/7 technical service. I am proud that we have shaped Elektrolas into a complete partner for the manufacturing industry.’

Own responsibility

Ask the Elektrolas team to describe Joost and there is soon admiration for his gut feeling and unlimited ideas. And for his perseverance and the boundless energy with which he runs half marathons. ‘At school, I could never sit still. I always want to be busy. The fact that I see and remember everything is fortunately my strength. I don't believe in hierarchy. I do believe in the personal responsibility of our people. That is why we share plans internally and I like to step back when I see that things are going well. The atmosphere within Elektrolas is very important to me. I believe in warmth and security. People should be able to do their work in a place where they feel comfortable. Hence the cosy office interior, the bar area where we can confer and a catered lunch every day.’

The welding workshop of the future

‘We challenge our relations to keep developing. With them, we share our vision of the welding workshop of the future. If we want to retain the manufacturing industry for the Netherlands, they will have to focus on smarter working, flexible working and digitalisation. Meanwhile, we also expect the demands on the end product to become increasingly stringent. Less weight, fewer transport movements and a reduction in cost price. Elektrolas' services are constantly adapting. We are ready for the future!’

Read more about Elektrolas

Read more about the Welding Workshop of the Future

Our Overall Approach

When it comes to welding, elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.