Michael

‘Being allowed to be part of this

gives me energy every time.’

Michael Hagelaars

Business development & Market innovation

T: +31 (0)6 53619541

E: michael@elektrolas.com

gives me energy every time.’

Michael Hagelaars

Business development & Market innovation

T: +31 (0)6 53619541

E: michael@elektrolas.com

The dynamics of the welding industry have gripped me

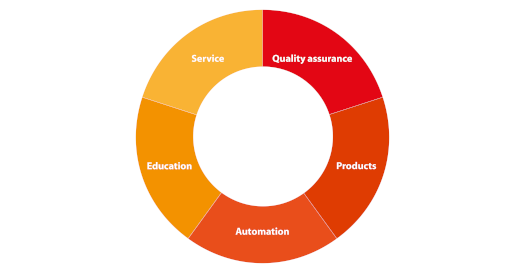

As Manager Business Development & Market Innovation, Michael Hagelaars has a helicopter view of all the processes Elektrolas carries out for customers. These are Quality Management and Training, everything around Product Sales and Rental, the Service Department and, of course, Automation. In other words, Elektrolas' complete Disc of Five. Michael closely follows market developments. He follows the trends affecting the welding field and always wants to anticipate them in the best possible way with Elektrolas' offering.

Production process

‘Elektrolas' customers are companies where welding is an essential part of the production process. Our added value does not stop at supplying machines and welding consumables. In the welding field, we therefore offer our customers a total package: all the services and products needed to be successful in their business and remain competitive. Our range of products and services is therefore continuously adapted to market developments, the requirements from standards and the type of work they want to perform.’

Elektrolas

After studying International Business and Languages - Michael himself prefers to describe it as Commercial Economics with languages - he joined Elektrolas in 2006. ‘The dynamics of the welding industry grabbed me. Enormously versatile; I think I would go crazy if I already knew today what the next week would look like. This morning I would be standing under a shipyard to demonstrate a welding mechanisation solution, tomorrow I would be making sales calls and the day after tomorrow I would be standing in a white coat, so to speak, in a laboratory doing materials research and destructive testing. Soon I became at home in the world of welding. Not only practically, but also when it comes to spotting trends and developments in time based on discussions with our customers. Thanks to technology, demand and supply, the market is constantly evolving. Those who do not adapt, fall over.’

NEN standards

‘That there are NEN standards for delivering a prescribed welding quality has of course been known for some time. But still not everyone wants to face the consequences. Of course it is good to trust each other - good cooperation cannot be captured in standards - but these standards were created for a reason. The more risk there is in the application for which the welding is intended, the more necessary it is to have tough requirements. Elektrolas provides in-house NIL skills training, certifies individuals and companies, draws up welding improvement plans and examines welding joints. In this way, for our customers to achieve optimum quality results is within reach.’

Flexibilisation of the labour market

‘The flexibilisation of the labour market is a trend that has been going on for some time. This means that employees should be able to be deployed according to need. In recent years, many long-term work processes have already disappeared from the Netherlands. Where once, in a factory, the same products rolled off the same conveyor belt year after year and the same people performed the same work, we increasingly see project-driven work. So companies are forced to scale up and down flexibly. For example, a new project requires a very specific welding process. Or a flexible deployment of capital goods, such as welding equipment, robots or cobots. Elektrolas has everything we need to respond to this.’

Automation

‘Now and in the coming years, we will see production processes become increasingly automated. Of course because it is difficult to find suitable new employees, but also because of the quality of the end product. Automation will eventually lead to a proportionally larger number of people in production companies dealing with safety and product traceability. Elektrolas will also continue to follow these developments. Not only through its sales and rental range, but also by offering applications for managing certificates and recording welding plans. Such as Our Welding Portal and Certibank®.’

Disc of Five

‘Elektrolas' offering is summarised in the Disk of Five. This consists of Quality Management, Products, Automation, Service and Training. These are the tools with which the Elektrolas team prepares customers for the future. Being allowed to be part of this gives me energy every time.’

More info on Quality Assurance

More info about Service

More about Education

More about Products

More about Automation

Production process

‘Elektrolas' customers are companies where welding is an essential part of the production process. Our added value does not stop at supplying machines and welding consumables. In the welding field, we therefore offer our customers a total package: all the services and products needed to be successful in their business and remain competitive. Our range of products and services is therefore continuously adapted to market developments, the requirements from standards and the type of work they want to perform.’

Elektrolas

After studying International Business and Languages - Michael himself prefers to describe it as Commercial Economics with languages - he joined Elektrolas in 2006. ‘The dynamics of the welding industry grabbed me. Enormously versatile; I think I would go crazy if I already knew today what the next week would look like. This morning I would be standing under a shipyard to demonstrate a welding mechanisation solution, tomorrow I would be making sales calls and the day after tomorrow I would be standing in a white coat, so to speak, in a laboratory doing materials research and destructive testing. Soon I became at home in the world of welding. Not only practically, but also when it comes to spotting trends and developments in time based on discussions with our customers. Thanks to technology, demand and supply, the market is constantly evolving. Those who do not adapt, fall over.’

NEN standards

‘That there are NEN standards for delivering a prescribed welding quality has of course been known for some time. But still not everyone wants to face the consequences. Of course it is good to trust each other - good cooperation cannot be captured in standards - but these standards were created for a reason. The more risk there is in the application for which the welding is intended, the more necessary it is to have tough requirements. Elektrolas provides in-house NIL skills training, certifies individuals and companies, draws up welding improvement plans and examines welding joints. In this way, for our customers to achieve optimum quality results is within reach.’

Flexibilisation of the labour market

‘The flexibilisation of the labour market is a trend that has been going on for some time. This means that employees should be able to be deployed according to need. In recent years, many long-term work processes have already disappeared from the Netherlands. Where once, in a factory, the same products rolled off the same conveyor belt year after year and the same people performed the same work, we increasingly see project-driven work. So companies are forced to scale up and down flexibly. For example, a new project requires a very specific welding process. Or a flexible deployment of capital goods, such as welding equipment, robots or cobots. Elektrolas has everything we need to respond to this.’

Automation

‘Now and in the coming years, we will see production processes become increasingly automated. Of course because it is difficult to find suitable new employees, but also because of the quality of the end product. Automation will eventually lead to a proportionally larger number of people in production companies dealing with safety and product traceability. Elektrolas will also continue to follow these developments. Not only through its sales and rental range, but also by offering applications for managing certificates and recording welding plans. Such as Our Welding Portal and Certibank®.’

Disc of Five

‘Elektrolas' offering is summarised in the Disk of Five. This consists of Quality Management, Products, Automation, Service and Training. These are the tools with which the Elektrolas team prepares customers for the future. Being allowed to be part of this gives me energy every time.’

More info on Quality Assurance

More info about Service

More about Education

More about Products

More about Automation

Our Overall Approach

When it comes to welding, elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.