Patrick

‘The work of a Technical Welding Consultant is

very black and white. Something is good or not.’

Patrick van Asperen

Technical Welding Consultant

T: +31 (0)6 18353894

E: patrick@elektrolas.com

very black and white. Something is good or not.’

Patrick van Asperen

Technical Welding Consultant

T: +31 (0)6 18353894

E: patrick@elektrolas.com

"Quality requires independent judgement"

Quality management is one of the services that make Elektrolas a total supplier in the welding field. Patrick van Asperen is one of our Welding Technical Advisors. An IWT'er (International Welding Technologist) with broad technical experience. Patrick has been with Elektrolas since 2019. Certifications, training, inspections and welding improvement processes are Patrick's daily challenges.

IWT'er

‘How two materials are joined together has always fascinated me. When I was about 16 years old, my father gave me a welding machine. I started welding on cars. Meanwhile, I got assignments for light construction work. Later - I was doing a welding course by then - I made all kinds of design objects for an artist. Once people knew I could weld, the demand for fencing, chimney caps and stainless steel exhaust hoods came naturally. After my Crafts 1 to 4 diplomas, I took framework courses and became an IWT officer.’

Ambition

Patrick successively became a welder, cooperating foreman, workshop chief and eventually welding coordinator. ‘I worked on onshore and offshore projects. Work where strict standards apply to the quality of welding. But times were changing. The company I worked for chose a new direction and focused more and more on mechanical engineering for the food industry. With that, the demands on the quality of my work changed. The welds had to be hygienic, but did not really offer me many challenges anymore from a technical point of view. I became Welding Technical Advisor at Elektrolas because my ambition lay in writing welding plans, supervising certifications, carrying out welding improvement projects, performing inspections and teaching.’

Melt

‘There is a huge need in the market for quality support. In a recent visual inspection of six projects, five were found not to be executed according to standards. Why is that? Knowledge is often in the mind of the welder who has been working on the project in the first place. If the correct way of working is not recorded, a staff change or illness is enough to drain that knowledge from the company. Through the intervention of a Welding Technical Advisor, a company ensures that it meets the prescribed requirements. We found welds that visually looked good without actually melting materials because the amperage was set too low. The parts were actually just stuck together. You can imagine what happens when a bridge is constructed in this way.’

Rescue team

Patrik's decisiveness and planned way of working are not entirely out of the blue. To illustrate, we come to his activities for the Rescue Brigade, one of his hobbies besides running, swimming, hiking and motorcycling. ‘I am a member of a unit of the National Rescue Fleet (NRV). This rescues drowning people from the water in emergencies. As an instructor, I give weekly lessons in the indoor swimming pool in Veghel to candidates who want to go for the Life Saver 1, 2 and 3 diploma. They first learn to save themselves and then to save another person in different ways. We have so-called 'dry rescues' from the shore and 'wet rescues' where the Life Saver rescues the drowning person by entering the water himself. Candidates who have mastered that can lead in major rescues, such as situations involving multiple drowning people.’

Independent

Patrick thus continues until the required result is demonstrably achieved. A quality that is inseparable from his job. ‘Quality Management is a separate department at Elektrolas. So separate from Sales, Rental and Service. The work of a Welding Consultant is very black and white. Something is good or not. Quality requires an independent judgement, without sales targets. Our clients need an objective insight to then know exactly how the welding process should be adjusted. This allows them to meet the requirements of the work. And that is exactly what my job entails.’

More info on Quality Assurance

More info on Education

Our Overall Approach

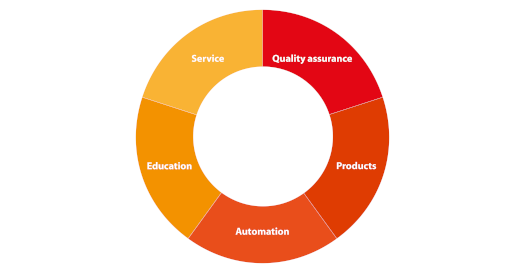

When it comes to welding, elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.