Engineering support

Our specialists can assess whether all the technical requirements needed to manufacture a product are in place at your company. Up to and including taking care of the inspection of the final product.

Quality and traceability of welding documentation

The importance of this support is that you are going to make a product that meets all the requirements set, with the right means and welding methods and the right qualifications. In this way we guarantee that you can demonstrably meet the agreed quality requirements. Traceability of welding documentation.

Furthermore, we also look at the product that needs to be made. That includes weld shapes, weld thicknesses and material types. Based on that, welding method descriptions (WPS) for the welder are drawn up and also the welder qualifications that the welder must meet for that product. An engineer knows a lot about inventing and designing. When it comes to welding-related standards, we can give him information to make a good makeable design. This ensures that on the shop floor, weldability is promoted.

Questions

Our overall approach

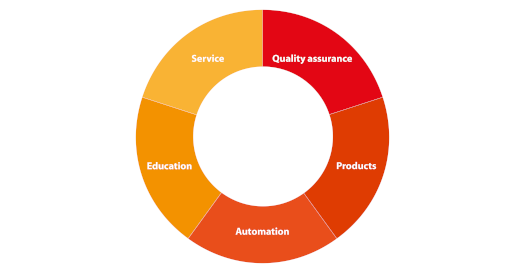

When it comes to welding, Elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.