External welding coördinator EN 1090

For the manufacture of steel and aluminum structures, the EU has established CE marking. Rules for manufacturers in these sectors are laid down in standard EN 1090. If you want to perform welding activities under execution classes 2, 3 or 4, you are obliged to appoint a welding coordinator.

Main tasks welding coordinator

The main task of a welding coordinator is to assess the requirements that a product must meet. This is done in the field of feasibility and weldability. In addition, they check whether the correct welding procedures are in place. If not, the welding coordinator examines whether these can be obtained in house or whether the work should be outsourced. In the latter case, he can check whether that company complies with the (welding) quality requirements of the product to be manufactured.

The welding coordinator's job also includes production planning: how quickly and how effectively can production be done. Furthermore, he reviews the approval of welding methods and welder qualifications and arranges the welding method description and work instructions. He manages welding consumables, with the appropriate certificates, and master materials. Is there any post-treatment needed or corrections to be made? Finally, he is responsible for the identification and traceability of the product with the corresponding reports.

Hire Elektrolas welding coordinators

Elektrolas offers a solution especially for companies who do not have their own welding coordinator. But also for companies who do have a welding coordinator Elektrolas can be a welcome support.

Directive EN ISO 14731 defines all tasks and responsibilities of the welding coordinator. Whether in steel construction, machine construction, shipbuilding, on-shore/off-shore or really specific customer requirements: Elektrolas has a specialist in welding coordination for each sector. Most of them have an IWT training (International Welding Technologist, EXC 3), supplemented by specific know-how and qualifications.

In the quotation phase of your project, our welding coordinator can already point out (possible) obstacles and how they can be avoided. This prevents extra costs being incurred or, even worse, subsequent damage. The entire process is recorded in writing, so that it is always possible to trace how and with what something was made (traceability). Something that can be important in case of any repairs later on.

More information

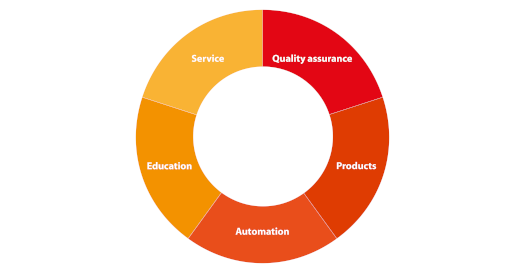

Our overall approach