Internal Audit: pre scan

Avoid expired documents

Too often we come across documents that have been expired for weeks, months or even over a year. The most common reason is often forgetfulness or lack of time, keeping the staff meaningfully up and running is then the priority. Still, we can't ignore it, when you as a company have invested effort and resources in a decent database of documents it is certainly worthwhile to have and keep it in order.

The discovery of expired certificates often happens when it is not convenient. An authority that can provide recertification must then be approached quickly. The costs for the recertification are often higher than the costs for maintaining the certificates.

Audits in three categories

Of course, the auditing of EN 1090 & EN -ISO 3834 by Elektrolas goes beyond handing out minors and majors; it also includes improving and advising on new welding techniques and processes. At Elektrolas we distinguish audits in 3 categories:

First party audit

Known as an internal audit. These audits are usually performed internally by your own staff, who are trained to do so. If you don't have those internal resources, the audits can also be conducted on your behalf by an outside company.

Second party audit

The supplier audit. These audits are usually conducted by lead auditors at your organization and are designed to ensure that the companies providing products/services to you are doing what they say they are doing. Again, these audits can be performed by an outside company if you don't have the internal resources.

Third party audit

Also known as a certification audit. These audits are always conducted by an auditor from a certification body. The purpose of these audits is to obtain certification of the relevant ISO standard such as EN 1090 or EN -ISO 3834 for which you have applied for certification.

Make an appointment

In many small and medium-sized companies, where welding coordination is a secondary task because it seldom comprises a full working week of activities, a certificate or document that should have been renewed or updated sometimes slips through. During an audit carried out by Elektrolas we can help you to stay ahead of such problems. If you would like to talk to us, please contact us at +31 (0)416-235036. Or leave your contact details.

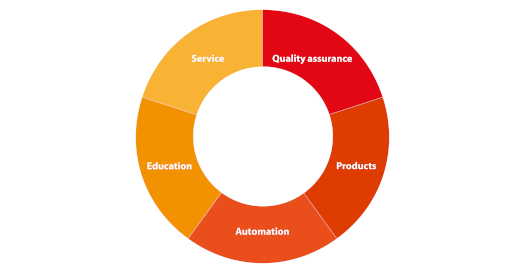

Our overall approach

When it comes to welding, Elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.