Personal protective equipment

A welder will have to wear Personal Protective Equipment (PPE) in many of his work activities.

The Occupational Health and Safety Act stipulates that an employer must provide Personal Protective Equipment (PPE) that complies with the requirements of the Goods Road Personal Protective Equipment Decree 2018. This is based on European regulations.

All products used for personal protection must be marked with the appropriate CE basic marking and expanded if required by the applicable standard according to the intended use.

Obligation of employer/employee

Both the employer and the employee have a number of duties they must meet around personal protective equipment.

Employer:

Employer:

- Provides the employee with the necessary PPE`s free of charge;

- Supervises the proper use of the PPE`s;

- Makes arrangements regarding maintenance and replacement with employees;

- Providing information and instructions on this;

- Indicates the situations in which the PPE`s should be used.

Employee:

- Properly use and maintain the PPE`s provided by the employer;

- Participate in instructions and information about the PPE`s;

- Check whether the CE mark is present and in good condition.

Onze totaalaanpak - De Schijf van Vijf

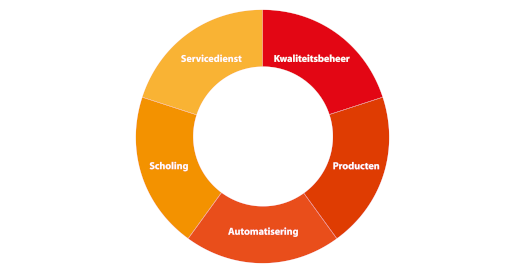

Alle kennis en middelen rond lasvragen hebben wij in eigen huis. Wij zijn één aanspreekpunt voor alle betrokkenen in het lasproces, van aanbesteding tot kwaliteitscontrole. Elektrolas is een totaalaanbieder op lasgebied. We borgen kwaliteit, geven scholing, innoveren processen, verkopen en verhuren producten en bieden service op lasbenodigdheden.. Dat is onze Schijf van Vijf. Vijf diensten die elkaar versterken. Zo zorgen wij dat onze klanten klaar zijn voor de toekomst.