QC Welding control

Welding work performed is subject to increasingly stringent requirements. To spot welding imperfections at an early stage, it is important to carry out a proper visual inspection according to established procedures. To do that, you need to have sufficient knowledge in the field of visual inspection of welding.

Visual weld inspection ISO 5817

Welding work performed is subject to increasingly stringent requirements. To spot welding imperfections at an early stage, it is important to carry out a proper visual inspection according to established procedures. To do that, you need to have sufficient knowledge in the field of visual inspection of welding.

Inspection Test Plan - ITP

Quality of a product cannot arise only at quality control, it must be included in the production process. To ensure this, important activities, requirements and acceptance criteria should be drawn up in advance. An Inspection and Test Plan is a good and important document for this.

In it, you describe the assessment methods and frequencies of inspections. This way, it is clear to all parties involved what is expected and after which operations so-called hold and witness points (stop points) are planned.

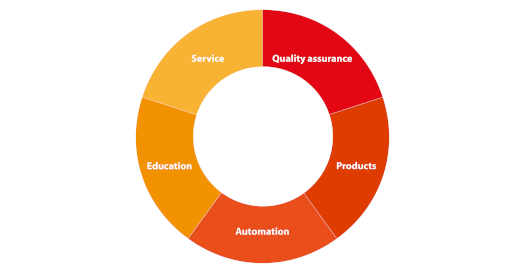

Our overall approach