Inspection of welding equipment

The NEN-EN-IEC 60974-4 is the European standard by which welding equipment must be safely inspected. In order to guarantee safe use of electrical installations as far as possible, this standard, like NEN 3140, prescribes that electrical installations must be inspected periodically. The safety inspection 60974-4 is the right solution for welding equipment! This standard is more comprehensive than the NEN 3140. If you are EN 1090 certified, verification (before validation) on all welding equipment must also be performed according to the NEN-EN-IEC 60974-14 standard.

Safety inspection of welding equipment

NEN-EN-IEC 60974-4 is the European standard by which welding equipment must be safely inspected. To ensure safe use of electrical installations as much as possible, this standard prescribes, just like the NEN 3140, that electrical installations must be periodically inspected. The safety inspection NEN-EN-IEC 60974-4 is the right solution for welding equipment. This standard is more comprehensive than the NEN 3140.

The NEN-EN-IEC 60974-4 prescribes that the welding machines must be clean and dry before inspection. This means that the machine must be provided with maintenance. According to the standard, this must be done by trained service personnel. Our service technicians are trained every year by our suppliers, EWM, Rehm and Hypertherm. They are authorized to perform inspections, repairs and examinations on all brands of welding equipment.

Our service engineers provide your machines with an inspection report. These reports are uploaded to Our Welding Portal so that you have a clear overview of your welding machines and their reports. A message will automatically appear in Our Welding Portal when your machines are due for another inspection.

The NEN-EN-IEC 60974-4 prescribes that the welding machines must be clean and dry before inspection. This means that the machine must be provided with maintenance. According to the standard, this must be done by trained service personnel. Our service technicians are trained every year by our suppliers, EWM, Rehm and Hypertherm. They are authorized to perform inspections, repairs and examinations on all brands of welding equipment.

Our service engineers provide your machines with an inspection report. These reports are uploaded to Our Welding Portal so that you have a clear overview of your welding machines and their reports. A message will automatically appear in Our Welding Portal when your machines are due for another inspection.

What is verification?

Welding verification is the process of checking the quality of the welded joint to ensure that it meets the specified requirements. There are different methods for welding verification depending on the specific requirements of the project and the type of welding.

What is validation?

Validation involves checking the display to ensure that the voltae and amerage indicated match reality. Also, the welding machine in question will be connected tot a calibrated measuring unit with a resistance box. The resistance box will compare the indicated amerage and voltage. Finally, the values and any deviations will be documented.

What is calibration?

Calibration of welding equipment is the process of testing the accuracy of welding equipment and adjusting it where nexessary. This is crucial because it ensures that the welding equipment functions correctly and that welds meet the specified requirements. There are several solutions for calibrating welding equipment, depending on the type of welding equipment.

Mandatory verification of EN 1090

The quality and safety requirements for obtaining a CE mark are becoming increasingly strict. If you are EN 1090 certified, your equipment must meet additional standards in the area of inspection and verification. Not only do you have to deal with the electrical safety inspection NEN-EN-IEC 60974-4, but all welding equipment must also be verified according to the NEN-EN-IEC 60974-14 standard.

The NEN-EN-IEC 60974-14 prescribes that the machine must be provided with a safety inspection, NEN-EN-IEC 60974-4, prior to verification.

The NEN-EN-IEC 60974-14 prescribes that the machine must be provided with a safety inspection, NEN-EN-IEC 60974-4, prior to verification.

- Maintenance: Annually

- Inspection: Annually and after any repair whereby the covers have been removed

- Verification: Annually and after any repair to current-carrying parts whereby the covers have been removed

Diode resistance bench

During welding inspections, Elektrolas uses the diode resistance bench to measure and regulate the current of the welding arc. specific welding parameters required for the welding joint are also examined and compared.

At Elektrolas, we deliberately use the diode resistor bank because it can filter the arc from the measurement process. This allows more accurate measurement and immediate correction of any defects. Via the "maintenance" button, we tell you more about our maintenance inspection process.

At Elektrolas, we deliberately use the diode resistor bank because it can filter the arc from the measurement process. This allows more accurate measurement and immediate correction of any defects. Via the "maintenance" button, we tell you more about our maintenance inspection process.

Make an appointment

Do you want to make an appointment for a safety inspection of your welding equipment? Let us contact you.

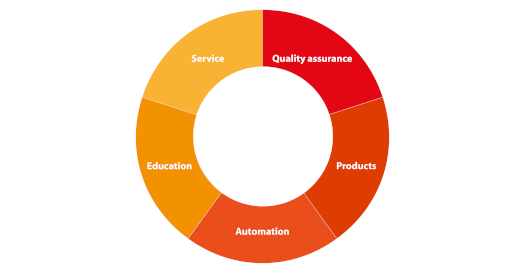

Our overall approach

When it comes to welding, elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.