Maintenance of welding equipment

Every day, small faults occur in welding equipment that are not necessary. Often, these failures are caused by slight wear of various parts of the welding machine. Periodic maintenance of the various components of the welding installation will drastically reduce machine breakdowns.

Annual maintenance

Minor machine malfunctions are considerably reduced, thus guaranteeing continuity. In addition, preventive maintenance also saves on high repair costs. Faults that are beyond the user's control can be ruled out almost immediately, which makes fault analysis faster.

Digital reporting

The maintenance certificates are placed in Our Welding Portal by our service technicians. This way you always have access to your machine park and it remains up to date. You can see at a glance which machine is due for maintenance. Because the system automatically detects this, we proactively schedule an appointment with you.

Secure welding quality through maintenance

Small hitches and failures cause irregular welds. The vulnerability of a welding installation can be divided into the following four parts:

Welding torch with cable package

The wearing parts in the torch are thermally stressed by high temperatures and radiation from the weld pool.

Wire feed case

Even a small imbalance in the wire feed system will result in an irregular weld.

Gas composition and gas installation/reducer valve

Good gas protection (without leakage) is necessary for a good weld.

Power source

The power source must be free of contamination and electrical problems. In addition, a periodic inspection is mandatory in many cases within the framework of occupational health and safety legislation.

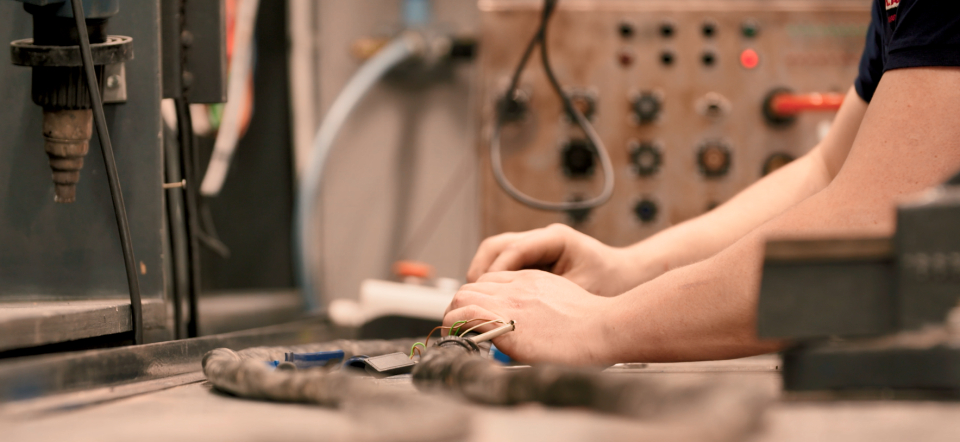

Welding torches repair

When repairing welding torches, our technicians use good tools, a crucial part of which is our welding torch test cabinet. The test cabinet is used by the mechanics to check all functionalities of the welding torches, such as gas flow, control current, pull current gas cable, etc. In this in-house developed test cabinet we have built in a functionality to check water hoses and water connections for water tightness with hot water (at 6 bar). Our technicians deliberately choose 40 degrees because leaks are more likely to be discovered at high temperatures. There will also be a visual inspection to see if everything is as it should be. As a double check, our mechanics will perform a test weld to make sure there are no more flaws.

Skilled service team

If you entrust Elektrolas with preventive maintenance of your welding machines, you will avoid much loss of production and maintain continuity. We have a skilled team of service technicians on hand to support you with the annual maintenance of your welding machines. Meet our service technicians.

Our overall approach