NEN 3140: Safety inspection of electrical tools

NEN 3140 is an independent standard that contains all relevant requirements for low voltage installations for the Netherlands. The Dutch law states that electrical installations and equipment must be safe and that work with or on these installations must be carried out safely. According to the Health and Safety Act, it is the employer's task to ensure that electrical installations and tools are safe to use. Employers must show what they have done to make this possible. This can be done through (periodic) maintenance and inspection.

NEN 3140 inspection by Elektrolas

With the latest equipment we test the electrical safety with regard to earth connections, insulation resistance, leakage current, differential current and contact current.

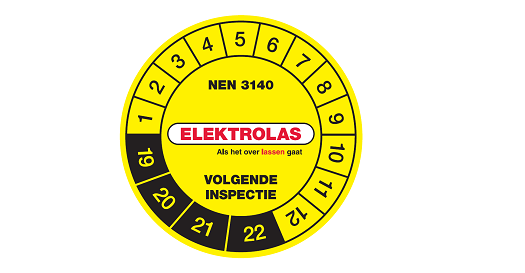

The inspection consists of visual inspection, measurements and tests with the safety meter. The results of this NEN 3140 inspection are recorded in an inspection certificate. In addition, the approved equipment is provided with a sticker, so that it is visible that the machine has been inspected and when the next inspection is required. If tools and/or extension cables are not acceptable according to the inspection, our service engineers can (in consultation) proceed directly to repair.

The machine list with the corresponding inspection reports is registered in our database and shared with you via Our Welding Portal. Via this same portal, you will automatically receive a notification when the equipment is due for its annual inspection. But by then we will probably have contacted you proactively.

The inspection consists of visual inspection, measurements and tests with the safety meter. The results of this NEN 3140 inspection are recorded in an inspection certificate. In addition, the approved equipment is provided with a sticker, so that it is visible that the machine has been inspected and when the next inspection is required. If tools and/or extension cables are not acceptable according to the inspection, our service engineers can (in consultation) proceed directly to repair.

The machine list with the corresponding inspection reports is registered in our database and shared with you via Our Welding Portal. Via this same portal, you will automatically receive a notification when the equipment is due for its annual inspection. But by then we will probably have contacted you proactively.

Obligation for the employer

The general requirements formulated in the Health and Safety Act have been worked out in concrete terms in the NEN 3140 standard with regard to electrical safety. This standard contains safety provisions aimed at preventing the risk of contact, fire and malfunctions. Not only installations and tools must be safe to use, also people who work on and in the vicinity of electrical installations must be instructed about safety. When you meet the provisions of the NEN 3140, you also meet the requirements of the ARBO legislation for the aspect of electrical safety.

Electrical work equipment is also referred to as electrical hand tools. Popularly described as "everything with a plug on it". Of course, the person in charge within a company must pay attention to a clear definition. For example, a lathe with a plug connected to it does not really fall under hand tools and should rather be included in the inspection of the fixed installation. It is important not to leave this category undefined.

In order to guarantee the safe use of electrical installations as much as possible, the standard prescribes that they must be inspected periodically.

Electrical work equipment is also referred to as electrical hand tools. Popularly described as "everything with a plug on it". Of course, the person in charge within a company must pay attention to a clear definition. For example, a lathe with a plug connected to it does not really fall under hand tools and should rather be included in the inspection of the fixed installation. It is important not to leave this category undefined.

In order to guarantee the safe use of electrical installations as much as possible, the standard prescribes that they must be inspected periodically.

Make an appointment

Would you like a safety inspection of the power tools in your company? Let us contact you.

Our overall approach

When it comes to welding, elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.