NEN-EN-IEC-60974-14: Verification of welding equipment

The quality and safety requirements for obtaining a CE mark are becoming increasingly stringent. If you are EN 1090 certified, your equipment must meet additional standards in the field of inspection and validation. Not only do you have to deal with electrical safety inspection IEC 60974-4, but all welding equipment must also be validated according to the NEN-EN-IEC 60974-14 standard.

Verification of welding equipment

NEN-EN-IEC 60974-14 states that verification (formerly validation) must be performed by a professional. It should be done once a year so that the welding parameters are reliable. Validation involves checking that the indicated amperes and voltages on the displays of the welding machine correspond to reality. The values read and any deviations from them are documented.

The verification of welding equipment can be done in different ways. However, the standard prescribes 2 different classes, the precision class and the standard class. Think about length of arc and resistance of the welding cables. To get these out we choose to measure with a diode resistor bank. Not the cheapest way, but the best. This gives a much more accurate measurement than a resistance bank or amperemeter that measures during welding.

For the verification, our Service Department uses a calibrated diode resistor bank. A diode resistor bank is a device used to measure or regulate voltage and current.

In good consultation

Together with the company, we outline what is needed. We report when another verification needs to be performed, so we can schedule it properly. One of our service engineers will come by at your convenience and everything can be done in the workshop. After the validation you will receive a validation report.

If the verification shows that the values deviate too much and fall outside the guidelines of the standard, we will have to see if the device can be recalibrated. Calibration is the re-adjustment of the welding machine.

Make an appointment

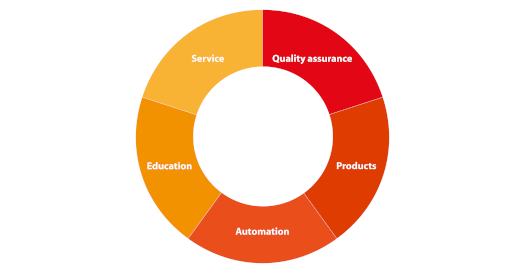

Our overall approach