Welding coordinator: coordinating and supervising welding work

A welding coordinator advises on the possibilities of performing requested welding work in the right way. He coordinates the preparation, supervises and carries out checks on the welding work. These have to meet the customer and production criteria and the corresponding standards. The welding coordinator can be found at companies where quality requirements are imposed on the products. Workshops and construction sites of construction, shipbuilding, food industry, offshore, petrochemical industry.

What a welding coordinator does?

The main task of a welding coordinator is to assess the requirements that a product must meet. In terms of feasibility and weldability. But a welding coordinator does even more:

- Take stock of whether the correct welding procedures are in place.

- In the case of outsourced work, monitoring whether that company adheres to the set quality requirements.

- Evaluate welding methods and welder qualifications.

- Provide welding method descriptions (WPS) and work instructions.

- Manage certificates of welding consumables.

- Have product traceability in order.

The welding coordinator is usually part of the quality department. Companies that are EN1090 certified are obliged to appoint a welding coordinator.

What competencies does a welding coordinator have

Good craftsmanship requires that the person possess competencies that define the job, the profession. A cobot welder should have:

Communicatively strong

Communicating and instructing personnel, discussions with suppliers, oral and written reporting is important.

Structured

Certificates of welding consumables, welding procedures, valid qualifications, work instructions and product traceability should be in order.

Independence

Quality requires independent judgment, without sales targets. It is good quality or not good quality, there is nothing in between.

What is part of the welding coordinator training?

In order to grow in the profession and possess the right competencies, a learning path has been set out for the welding coordinator. This consists of welding training, welding courses and workshops.

- Manual skills training (one of the four levels)

- Welding coordinator training (EWCP)

- Visual welding inspector training level 2 (VTw-2)

- Workshop on quality assurance in welding technology

- Workshop Certified Welding according to ISO 9606 and 15614

Growing in the work develops the talent, the craftsmanship increases, the appreciation increases, other connections are made, and solutions are found faster.

Career opportunities for a welding coordinator

Are you ambitious and do you want to grow within welding technology. Then there are several positions / professions for which you can continue to learn:

- Welding inspector

- Welding engineer

Elektrolas supports operational and managerial staff to take the right steps by providing them with professional training.

Elektrolas advises the right route

By taking a project-based approach to employee training, you can make strategic decisions. We advise you on the long-term direction you can take with your employees and the training you need to achieve that. We have our own welding school in Waalwijk, where we offer all training courses and workshops. This makes the flow of the learning process very smooth. Would you like to talk to us about a training program for cobot welders or do you want to look at your entire workforce together? Contact our Training Department at 0416-235036 or lasschool@elektrolas.com. You can also leave your details and we will contact you.

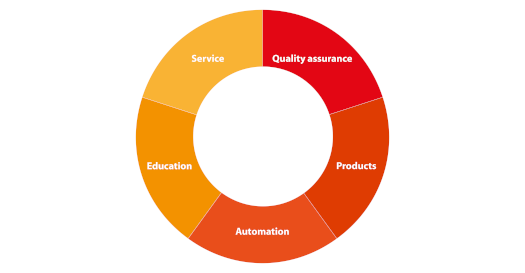

Our Overall Approach

When it comes to welding, elektrolas has all the knowledge and resources in-house. We are a point of contact for all those involved in the welding process, from tendering to quality control. We are a total provider in the welding field. We secure quality, offer training, sell, rent and service on welding equipment. This is our disc-of-five. Five services that reinforce each other. That is how we ensure that our customers are ready for the future.