News Update: Our Thije proudly tells...

We would like to inform you of the latest developments within Elektrolas and welding technology via our newsletter. In this newsletter:

- Our Thije proudly tells...

- Aggressive abrasive requires heavier grinder.

- Masterclass Quality Assurance in welding technology.

- We are looking for a welding teacher.

- Elektrolas organises GLOW

Our Thije proudly tells

"As a technician, you are sometimes quick to say that something cannot be done. But if you then think about it for a moment, you find out that it is possible after all. That's exactly where Elektrolas' strength lies." Thije van Delft has been with us for 10 years and leads the new COBOT centre.

Revolutionary, enthusiastic and determined is what characterises Elektrolas. But so do our employees. Thije tells how he and his team ensure that customers get the automation solution that suits their production.

Revolutionary, enthusiastic and determined is what characterises Elektrolas. But so do our employees. Thije tells how he and his team ensure that customers get the automation solution that suits their production.

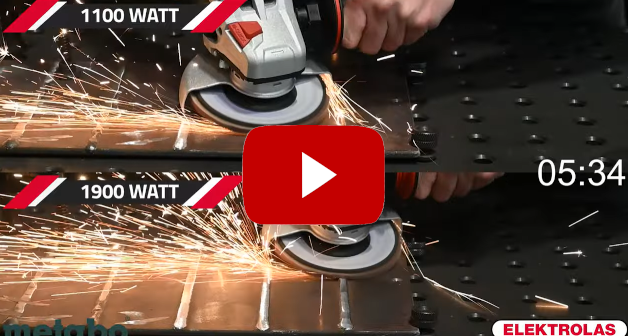

Aggressive abrasive requires heavier grinder

What we often see is a light grinder being used in combination with an aggressive abrasive, such as 3M Cubtron III, VSM Actirox, Pferd Victograin or Cibo's FX discs. As a result, both fail to perform properly. The right match between grinder and abrasive is crucial. As abrasives have become more aggressive, a lighter grinder has to work harder than it actually can. As a result, grinding takes longer and its lifespan is shorter.

In the video above, we demonstrate two grinders: the 1100-watt and the 1900-watt, both using the same abrasive. As you will see, there is a significant difference between the performance of the grinders. Would you like to experience for yourself how the grinders behave during your work? Elektrolas and Metabo will come to you! Make an appointment in advance.

In the video above, we demonstrate two grinders: the 1100-watt and the 1900-watt, both using the same abrasive. As you will see, there is a significant difference between the performance of the grinders. Would you like to experience for yourself how the grinders behave during your work? Elektrolas and Metabo will come to you! Make an appointment in advance.

Masterclass Quality Assurance in welding technology

Clients ask for welding documents that show that your welding quality is guaranteed. This is also compulsory under European (EN 1090) and international (ISO 3834) directives. Would you also like to know how to guarantee welding quality within your organisation and/or with contractors?

Sign up for the Masterclass Quality Assurance in welding technology on Thursday 14 March from 13.00 - 17.00. The costs for participation are 175 (excluding VAT). Read more about the topics covered during the masterclass.

Sign up for the Masterclass Quality Assurance in welding technology on Thursday 14 March from 13.00 - 17.00. The costs for participation are 175 (excluding VAT). Read more about the topics covered during the masterclass.

We are looking for a welding teacher

The Elektrolas Welding School continues to grow. As a result, we can make good use of additional welding teachers. We are looking for a full-time/part-time experienced professional. Someone who has what it takes to impart his knowledge of welding and working in the car body repair industry. Lessons will be given during the day in both English and Dutch.

Would you like to join our team or do you know someone who qualifies, we would like to hear from you. Self-employed or salaried, both are welcome. Contact Joost van den Hooven at joost@elektrolas.com or 06-25108991.

Would you like to join our team or do you know someone who qualifies, we would like to hear from you. Self-employed or salaried, both are welcome. Contact Joost van den Hooven at joost@elektrolas.com or 06-25108991.

Elektrolas organises GLOW

'Health, Lifestyle & Development Weeks' is what Elektrolas GLOW stands for. During the entire month of March, all our employees will be challenged at various workshops, activities and challenges. They will discover how small adjustments on a physical, mental and social level in the daily routine have major positive effects on their overall health.

Would you like to stay up to date with our GLOW activities? Follow us on our socials LinkedIn, Instagram and Facebook. You can join the challenges too, challenge yourself!

Would you like to stay up to date with our GLOW activities? Follow us on our socials LinkedIn, Instagram and Facebook. You can join the challenges too, challenge yourself!